Prism ViaTec™ is a family of performance oriented polymers used to modify asphalt products. ViaTec, a sustainable polymer created from recycled tire feedstock, is intended to be used as a stand-alone additive or incorporated with other polymers for additional benefit.

ViaTec Features:

Designed to modify asphalt systems in a broad range of applications:

Hot Mix

Asphalt Emulsions

Crack Seal

Asphalt Roofing

Functional in many different asphalt bases –

(Tested with Table I and Table II asphalts)

Widens PG Grades by improving both upper and lower ends

Does not exhibit settlement issues

ViaTec Benefits:

Manufactured in US

Not tied to crude oil markets = less price fluctuations

Sustainable – manufactured from recycled materials

Lower in greenhouse gas emissions than virgin polymers

Add at the plant or in the field as a dry additive

Blends easily and produces high solubility (~99 %) after 30-45 minutes @ 300-325F

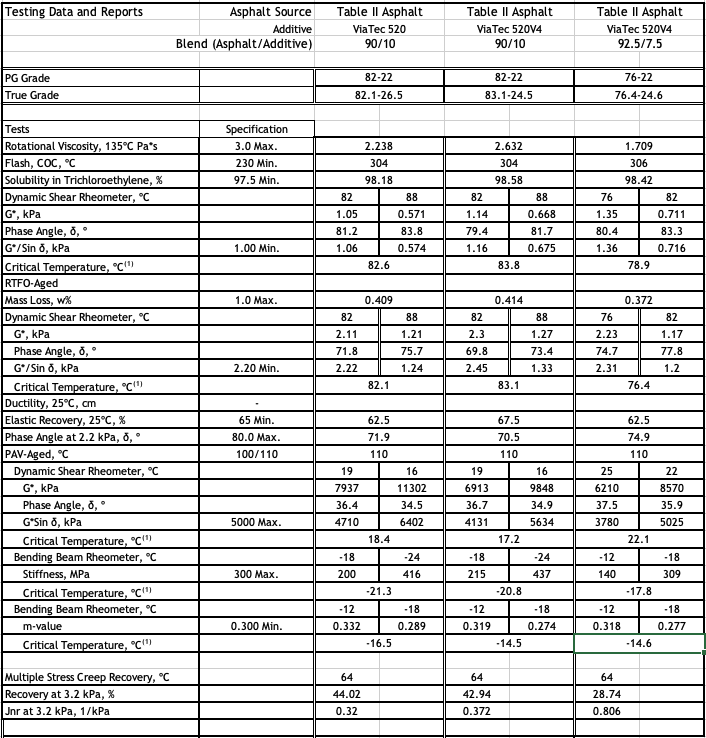

ViaTec testing results @ 10% and 7.5% addition rate in a standard Table II asphalt:

Packaging and Contact Information:

Dry additive in 2000# Supersacks

FOB Sodus, NY

For more information email: sales@prismww.com or call:

Scott Dmytrow @ (916) 825.9415 or Kenney Boyd @ (206) 715.721

Download the ViaTec Brochure