Prism Worldwide Unveils Breakthrough Technologies That Redefine Tire Recycling and Sustainable Manufacturing

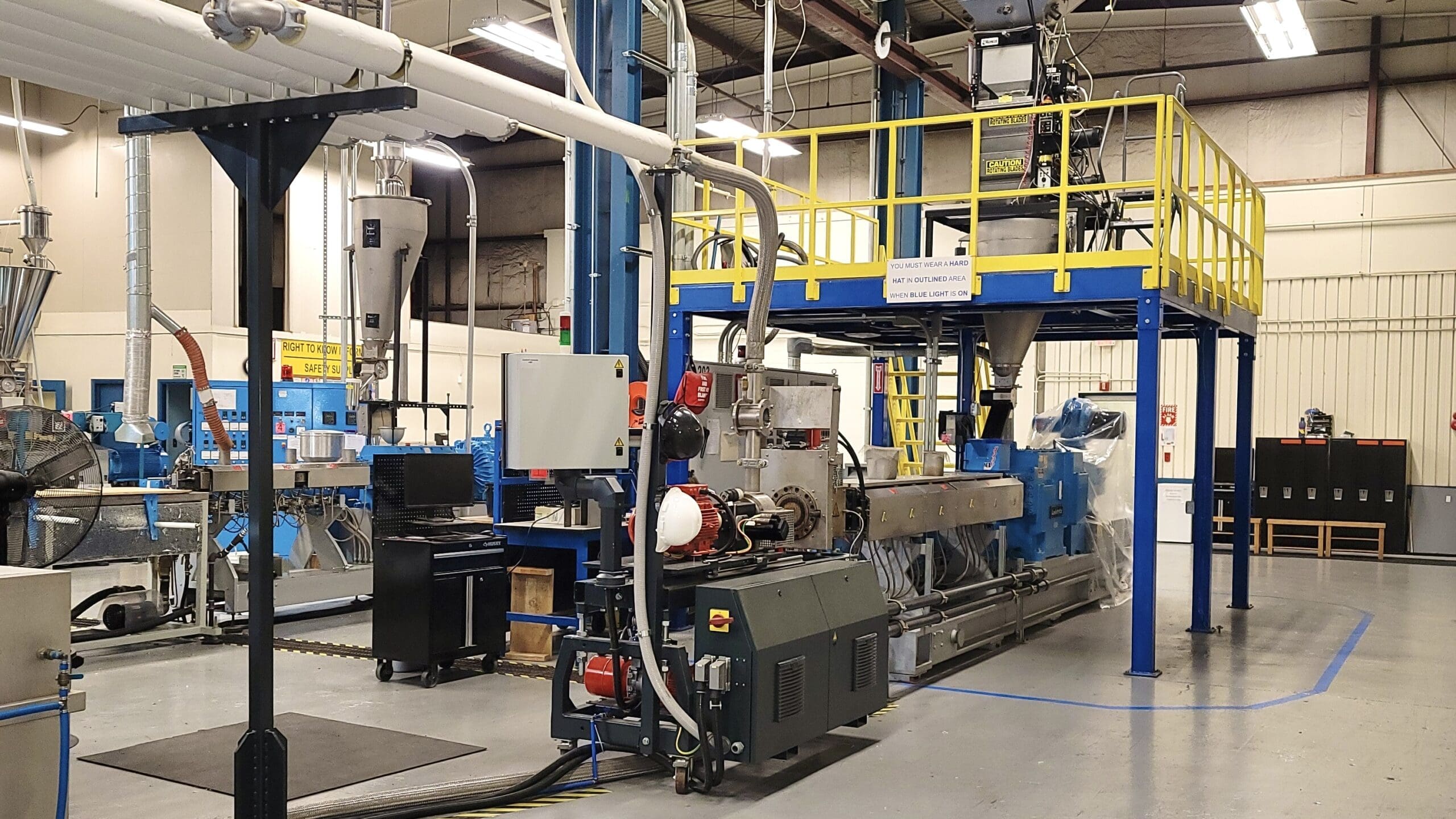

Prism’s breakthrough technology significantly reduces the persistent odor in recycled tire materials and plastics, making them suitable for indoor use in vehicles, homes, and consumer