SUSTAINABILITY

& ENVIROnMENT

Rubber...

is used in over 40,000 commercial products. These days, rubber is crucial to transportation, household products and so much more. That’s why we’re introducing a new solution that reinvents the recycling process at a molecular level. This solution means more recycled rubber gets used rather than thrown away along with saving more natural resources.

Current System

An end-of-life tire is ground down to make crumb rubber or burned as tire derived fuel. There is no further recycling possible.

U.S. Tire Manufacturers Association – 2019 U.S. Scrap Tire Management Summary

Resources / Articles

Prism Worldwide Commercializes TPE Derived from End-of-Life Tires

Prism Worldwide announces the commercial availability of Ancora™ C-1000 Thermoplastic Elastomer, which contains 50% post-consumer recycle content derived from end-of-life tires. Kirkland WA, May 3, 2023. Prism Worldwide (Prism), a clean technology company, is pleased to announce the commercial availability of AncoraTM C-1000 Thermoplastic Elastomer (TPE). Based on Prism’s patented technology, Ancora™ C-1000 contains a

Prism Worldwide acquires CRC Polymer Systems

Prism Worldwide enhances their manufacturing and compounding capabilities. Kirkland WA, 11/02/2022. Prism Worldwide (Prism), a clean technology company, has acquired CRC Polymer Systems (CRC), a custom compounding company supplying compounds, resins, and colors to the plastics industry. “We are pleased to have found an ideal partner in CRC,” said Bob Abramowitz, CEO of Prism. “The

New Environmentally Beneficial Materials and Applications Introduced

Kirkland, Washington – Prism Worldwide, a clean technology and innovation startup company manufacturing in the US, has released its new website. The modern design and content ties in with the company’s continued growth and expansion and shows how Prism is improving the environment by upcycling materials and removing waste from landfills. Prism’s new website explains

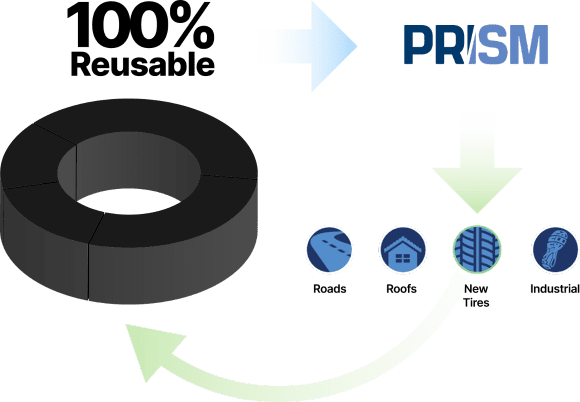

Prism™ System

When PTR™ is used in a new tire, the rubber can be recycled again and again – creating a stronger rubber with each cycle.