SUSTAINABILITY

& ENVIROnMENT

Rubber...

is used in over 40,000 commercial products. These days, rubber is crucial to transportation, household products and so much more. That’s why we’re introducing a new solution that reinvents the recycling process at a molecular level. This solution means more recycled rubber gets used rather than thrown away along with saving more natural resources.

Current System

An end-of-life tire is ground down to make crumb rubber or burned as tire derived fuel. There is no further recycling possible.

U.S. Tire Manufacturers Association – 2019 U.S. Scrap Tire Management Summary

Resources / Articles

Team Growth at Prism

At Prism Worldwide, we’ve had an incredibly productive first quarter. We built tremendous talent in our team with the addition of: Mark Kinkelaar, Chief Commercial Officer Sharene Nelson, Chief Financial Officer. Mark brings a wealth of sales, marketing and technical experience. Sharene comes to us from the sustainable forestry business. The ability to attract talented

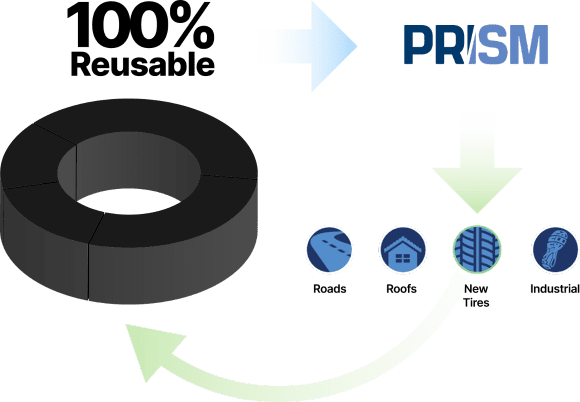

Prism™ System

When PTR™ is used in a new tire, the rubber can be recycled again and again – creating a stronger rubber with each cycle.