Prism at the 2025 SPE TPO Conference

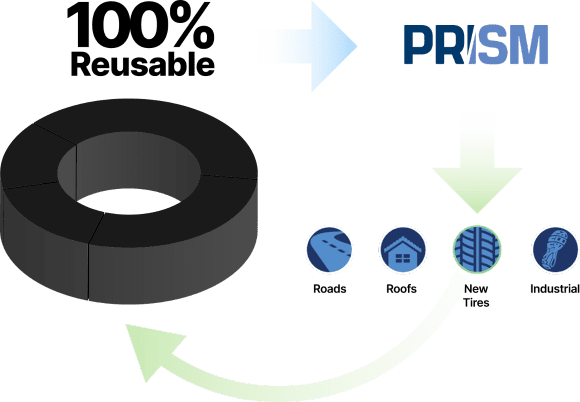

We will be exhibiting at the 2025 SPE TPO Conference from September 29th to October 1st. Visit us at booth 51 to learn more about our high-performance circular polymer materials or contact us at sales@prismww.com. ● ANCORAᵀᴹ thermoplastic elastomer compounds based on post consumer recycle content from end-of-vehicle life tires ● ENNOVAᵀᴹ TPO compounds with up to