WAVEBOND™

HALO™

The conclusion to an endless pothole repair cycle.

Configurable

Flat Panels

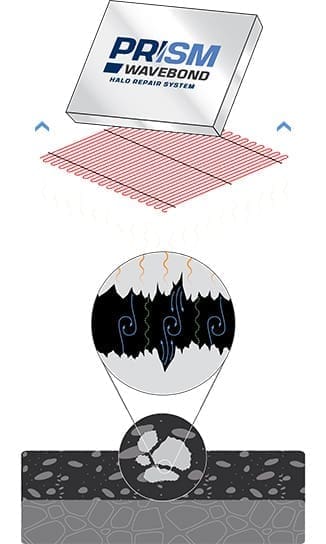

For the very first time we are using the existing binder, phononic waves and Prism thermoplastic rubber to create a permanent fix to potholes – and an end to the insane, endless pothole repair cycle. WaveBond™ HALO™ Flat Panels are attached to a portable platform, this high-speed process is the first step towards smoother, safer roads and communities.

Stronger, Permanent

Repairs

Adding PTR™

We then add the critical component of PTR™ to enhance and strengthen the existing pavement materials that have been heated. PTR™ adds the value that only a fully crosslinkable thermoplastic rubber from recycled tires can bring.

No Open Flames

HALO™ Pulse Waves heat only the binder around the aggregate into a liquid form that flows and moves. It can then be re-bonded with new materials.

The WaveBond Tunnel System takes mountains of RAP and creates with Prism’s PTR enhanced, 100% re-useable hot mix asphalt. This system allows the recovery of existing, brittle asphalt on location or at a RAP material storage yard.

On Site

Allows the recovery of existing, brittle asphalt on location or at a RAP material storage yard

Reuse Existing Binder

Reuse of existing asphalt binder reduces need for new binder by up to 80%

Transforms RAP

Transforms RAP stockpiles into PTR™ Enhanced HMA on site

WaveBond™ HALO™ Flat Panels, a portable platform, and a crew can move to trouble spots quickly and efficiently without smoke, fire, RAP trips, and longer traffic delays. This high-speed process, in conjunction with our PTR additive for ready mix repair material, creates a permanent fix to pothole issues.

DURABLE

More durable binders = less road failures

PERMANENT

In conjunction with PTR™ creates a permanent fix.

FIRST

The first on site repair to interfuse existing binder.

EFFICIENT

A permanent repair in 15 minutes or less.

CLEAN

No Smoke, No Burn, No Problem.